Moly Spray Lube

Moly Spray Lube is a dry-film lubricant which works perfectly for lead bullets. Applied directly from a pressurized spray can, it forms a durable, dark-colored film on the surface of lead swaged bullets, effectively preventing barrel fouling and leading at moderate velocities suitable for soft lead bullets.

Key Features:

- Effective Lubrication: Forms a dry, dark-colored film on lead bullets, reducing friction and preventing barrel fouling.

- Quick Drying: Dries in 15-20 minutes, allowing for efficient loading and shooting.

- High Coverage: One can provides sufficient coating for several thousand bullets when applied correctly.

Usage Instructions:

- Preparation: Ensure lead swaged bullets are clean and free from contaminants.

- Application: Hold the spray can approximately 6-8 inches from the bullet surface. Apply a light, even coat, ensuring not to soak the bullets or allow dripping. A thin film is more effective than a heavy build-up, which may be scraped off when the bullet is seated.

- Drying: Allow the coated bullets to dry for 15-20 minutes before loading.

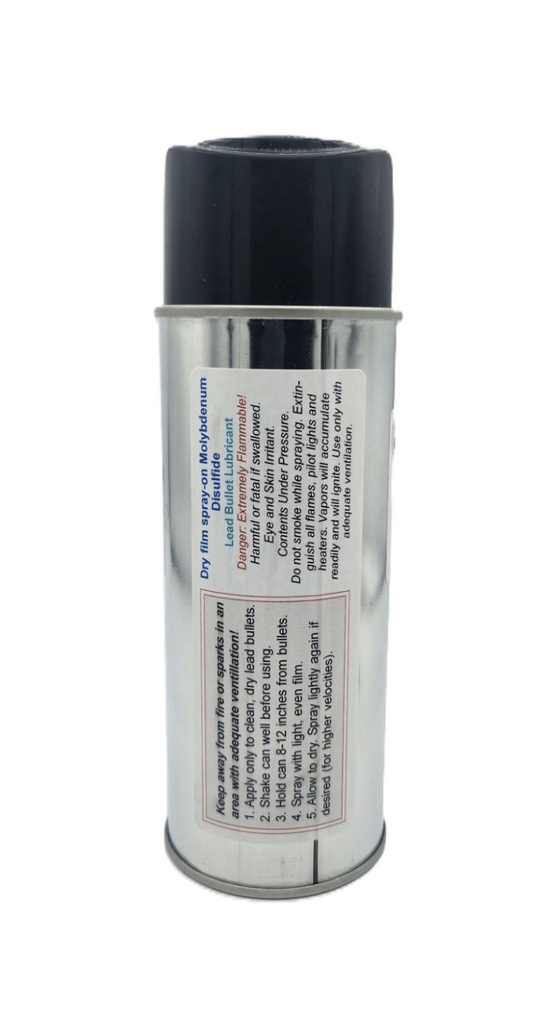

Safety Precautions:

- Flammability: The spray is highly flammable; do not use around open flames.

- Ventilation: Use only in well-ventilated areas to avoid inhaling fumes.

- Application: Apply sparingly in a light spray; do not soak the bullets or allow to drip.

Enhance your bullet performance and maintain barrel cleanliness with Corbin Moly Spray Lube, the preferred choice for lead bullet lubrication.

- Main Purpose: Prevents fouling and leading of the barrel

- Compatibility: Suitable for lead swaged bullets

- Features: Quick-drying, applied from a pressurized spray can

- Additional Info: Contains molybdenum disulfide, flammable, use in well-ventilated areas

Benefits

- Efficiency: Quick-drying formula allows you to continue with your reloading process swiftly.

- Quality: Contains molybdenum disulfide that bonds to the surface of the bullet, enhancing performance.

- Ease of Use: Comes in a pressurized spray can for easy application.

| Shipping Weight | 15 oz |

| Material Weight | 11 oz |

| Suspension System | Aerosol |

Hold the spray can approximately 6-8 inches from the bullet surface. Apply a light, even coat, ensuring not to soak the bullets or allow dripping. A thin film is more effective than a heavy build-up, which may be scraped off when the bullet is seated.

Moly Spray Lube can reduce friction between the bullet and barrel, potentially leading to less barrel fouling and easier cleaning. However, its impact on accuracy and velocity can vary, and some shooters have reported mixed results.

Yes, there are other lubricants and coatings available for lead bullets, such as traditional wax-based lubes and polymer coatings. The choice of lubricant depends on personal preference, shooting conditions, and desired performance characteristics. This is a quick and easy solution.

After shooting moly-coated bullets, it's important to clean the barrel to remove moly residues. Some shooters have used products like Kroll oil to aid in cleaning moly from the bore.