Product Description

Corbin Swage Lube (CSL-2) is the ultimate natural swaging lubricant, specially formulated for bullet swaging and jacket drawing dies. Available in 16-oz containers, it reduces friction, wear, and rust, ensuring peak performance.

- Main Purpose: Specially formulated for bullet swaging and jacket drawing dies

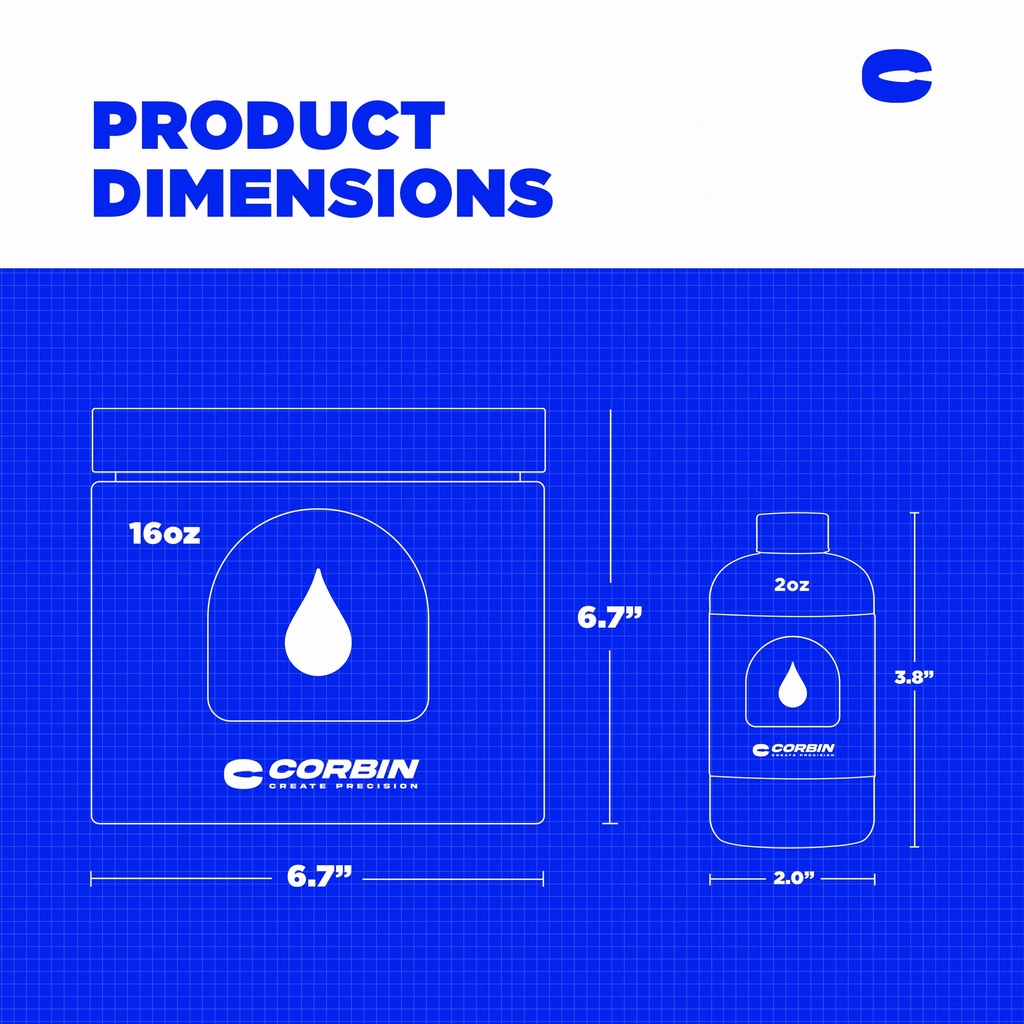

- Form Factor: Available in 16-oz containers

- Special Features: Non-flammable, non-toxic, and washes off easily

Benefits

- Reduced Friction: Ensures smooth operation in bullet swaging and jacket drawing

- Versatility: Also serves as a case sizing and reloading lubricant, with applications in aerospace and pipe fitting

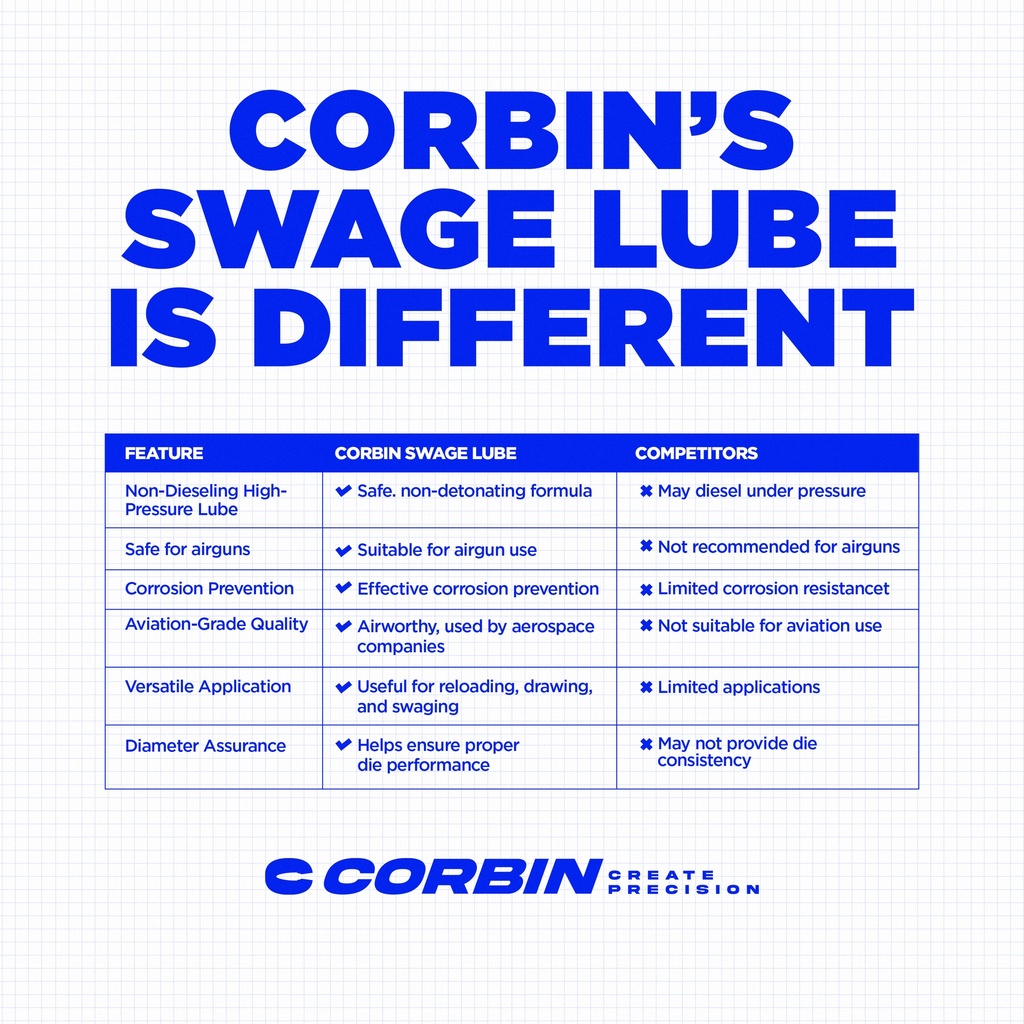

- High-Pressure Resistance: Unlike petroleum-based lubes, resists high pressures without diesel or detonation

- Easy Cleanup: Easily washes off your hands and equipment

- Long-Term Protection: Protects dies during storage

| Material Material | Organic Compounds (Proprietary) Organic Compounds (Proprietary) |

| Consistency Consistency | Solid and Smooth at Room Temp Solid and Smooth at Room Temp |

| Container Container | 3.5" Wide Mouth Squeeze Bottle |

| Shipping Weight Shipping Weight | 1 lb 0.25 lbs |

| Volume Volume | 16 oz 2 oz |

Swage lube is a crucial component when swaging bullets for two main reasons. First, it provides essential lubrication to reduce friction and heat during the high-pressure swaging process, helping to protect the equipment and ensure a smoother operation. Second, it helps dissipate heat, preventing potential damage to the bullets or swaging dies and maintaining the desired bullet shape and properties. Swage lube is essential for producing accurate and high-quality bullets for various applications.

Typically, you'll find guidelines in the user manual or instructions provided with your swaging equipment. It's important to follow these guidelines to ensure that you're using the right amount of swage lube for your particular setup. In general, you should apply a thin, even coat of swage lube to both the bullet and the inside of the swaging dies. Using too much lube can lead to issues like excessive lubricant buildup, which can affect the quality of the swaged bullets. On the other hand, using too little lube can result in increased friction and heat during the swaging process. To determine the exact amount of swage lube to use, consult Corbin's recommendations or reach out to us directly if you're unsure. We can provide you with specific instructions tailored to your equipment and the type of bullets you're swaging.

Swage lube will ensure that parts will not get stuck together. This can happen between the jacket and a punch, or a die and a jacket. Each situation is differently, but generally you want the punch to release the jacket, and the die to hold onto the jacket so it can be ejected by the ejection pin. If you are concerned about a specific situation, please contact Corbin's customer support.

Yes. We supply Corbin Swage Lube to many different industries which include construction, aerospace, and others. Swage lube is an excellent lubricant, and very safe to use, try it in other applications and let us know what you think.

?unique=f94ddaa)

?unique=f94ddaa)