Bonded core bullets normally retain from 90 to 100 percent of their weight after expanding, and can be more accurate in high acceleration loads because the core cannot slip or turn separately from the jacket. Corbin has provided the easiest and most effective form of diffusion bonding (molecular migration of excited atoms of the lead core across the boundry into the copper matrix of the jacket) for over 25 years, helping hundreds of custom bullet businesses around the world to provide shooters with top quality bonded bullets.

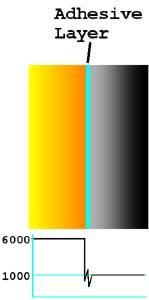

Unlike solder, glue, or mechanical fastening, the diffusion bonding process creates a tensile strength gradient across the jacket/core boundry (rather than a sudden step or change in tensile strength). When subjected to high impact force, a boundry junction with an instant step change from the 6,000 or more psi tensile strength of the jacket into the 1,000 psi tensile strength of the core will tend to channel all the force into this area, causing the highest differential in stress to occur at the boundry layer. The glued, mechanically bound, or soldered layer then acts like a stress riser, and peels the core away from the jacket because of the presence of a layer of oxide and carbonate on both the lead and the copper. The strength of a glued bond is always limited by the substrate or material to which it is fastened. No matter how strong the glue, all it can do is grip the oxide layer, which is peeled off under high stress. A diffusion zone lets the lead actually penetrate into the jacket, so that there is a smooth transition zone to move the stress into the lead core, causing it to peel back with the jacket when expansion occurs.

The glued, mechanically bound, or soldered layer then acts like a stress riser, and peels the core away from the jacket because of the presence of a layer of oxide and carbonate on both the lead and the copper. The strength of a glued bond is always limited by the substrate or material to which it is fastened. No matter how strong the glue, all it can do is grip the oxide layer, which is peeled off under high stress. A diffusion zone lets the lead actually penetrate into the jacket, so that there is a smooth transition zone to move the stress into the lead core, causing it to peel back with the jacket when expansion occurs. Under an electron microscope, atoms of lead can be observed as deep as 3 microns into the jacket material after a few seconds of bonding time. Allowing the lead to penetrate into the copper provides a much stronger bond than is possible with any form of surface adhesive. Corbin Core Bond provides two actions to make this bonding possible. First, it removes the oxides and carbonates momentarily from both the lead and the copper, allowing pure metalic lead and pure metalic copper to be in contact with each other under elevated temperature. Second, it lowers the surface tension of the molten lead to allow the excited lead atoms to "wet" the surface of the copper rather than pulling back from it as the lead would do without the surfectant action, so that penetration can take place.

Under an electron microscope, atoms of lead can be observed as deep as 3 microns into the jacket material after a few seconds of bonding time. Allowing the lead to penetrate into the copper provides a much stronger bond than is possible with any form of surface adhesive. Corbin Core Bond provides two actions to make this bonding possible. First, it removes the oxides and carbonates momentarily from both the lead and the copper, allowing pure metalic lead and pure metalic copper to be in contact with each other under elevated temperature. Second, it lowers the surface tension of the molten lead to allow the excited lead atoms to "wet" the surface of the copper rather than pulling back from it as the lead would do without the surfectant action, so that penetration can take place.

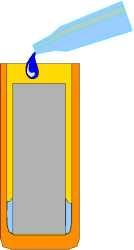

Corbin Core Bond is available in 2-ounce experimenter's size, CCB-2, or in the custom bullet maker's 16-ounce size, CCB-16. Larger quantities are available (such as gallon and five gallon containers) but are seldom needed except for very large production operations. One or two drops per bullet is all it takes for normal bonding. Bonding starts with a core to jacket diameter match that allows the core at least .001 inches of "gap" all the way to the bottom of the jacket. Cores which do not drop freely to the bottom of the jacket will trap air or Core Bond liquid and may be blown out with some force when the jacket is heated. Always make certain that the core you plan to use is small enough to allow at least this .001 loose fit, and preferably closer to .005 inches.

Bonding starts with a core to jacket diameter match that allows the core at least .001 inches of "gap" all the way to the bottom of the jacket. Cores which do not drop freely to the bottom of the jacket will trap air or Core Bond liquid and may be blown out with some force when the jacket is heated. Always make certain that the core you plan to use is small enough to allow at least this .001 loose fit, and preferably closer to .005 inches.

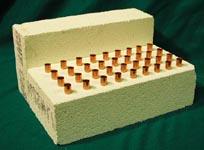

The core begins as a piece of lead wire, which is placed in a core swage die and brought to exact weight. The proper weight is the desired bullet weight less the weight of the jacket. After making the desired number of cores, clean them by sloshing in a solvent such as acetone or alcohol. Corbin also makes a cleaning solvent for disolving lubricants and oils (CCS-16). The jacket should also be cleaned by shaking in a container of solvent, then removed and allowed to dry completely. Once the core and jackets are dry, the jackets can be placed upright in a holder that will withstand direct flame. Corbin offers a ceramic heat treatment block that can easily be drilled with a masonry bit or even a standard wood bit. A pattern of 32 holes per brick can be made using the template that comes with the Corbin BL-KIT (two heat treatment blocks). One block should be drilled, and the other can be used as a backstop for the flames, to reflect the heat back on the reverse side of the jackets.

The jacket should also be cleaned by shaking in a container of solvent, then removed and allowed to dry completely. Once the core and jackets are dry, the jackets can be placed upright in a holder that will withstand direct flame. Corbin offers a ceramic heat treatment block that can easily be drilled with a masonry bit or even a standard wood bit. A pattern of 32 holes per brick can be made using the template that comes with the Corbin BL-KIT (two heat treatment blocks). One block should be drilled, and the other can be used as a backstop for the flames, to reflect the heat back on the reverse side of the jackets.

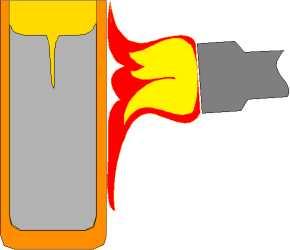

Drill about half the jacket length into the block. Set the jackets in the block, mouth up. Set the second block against the back edge of the drilled block, on its narrow edge, to act as a heat shield for the back side. Drop cores into each of the jackets. Again, the cores must fit all the way to the bottom of the jacket. Do not use oversize cores. Place one or two drops of Corbin Core Bond in each jacket, so it runs down the sides of the core. Then use an ordinary propane torch to heat the jackets so that the lead melts in each jacket. This will happen quickly, a few seconds per jacket. Move the flame along evenly, so each jacket is heated the same amount. When the cores have all melted, turn off the flame and allow the jackets to cool. When they are cool enough to touch, put the jackets in a container of boiling water, add a tablespoon of baking soda, and boil them for about a minute. Then spread them all out on a towel to dry of their own heat.

Place one or two drops of Corbin Core Bond in each jacket, so it runs down the sides of the core. Then use an ordinary propane torch to heat the jackets so that the lead melts in each jacket. This will happen quickly, a few seconds per jacket. Move the flame along evenly, so each jacket is heated the same amount. When the cores have all melted, turn off the flame and allow the jackets to cool. When they are cool enough to touch, put the jackets in a container of boiling water, add a tablespoon of baking soda, and boil them for about a minute. Then spread them all out on a towel to dry of their own heat.

When they have cooled and dried, examine them to see if there is a shrink hole in the core and the edges of the core have flowed up the side of the jacket slightly. If any cores display a dome rather than a cup shape, it means they were not properly bonded. Causes of failure to bond are usually traced to lubricant in the jacket or on the core that was not cleaned off, insufficient heat or applying the heat too slowly so that the Core Bond was boiled away before the lead melted, or the use of a core material that is not compatible with the bonding technique.

After the jackets and cores have been inspected, they are then swaged just as if they had not been bonded. Bonding the core does not expand the jacket, and it does not remove voids that might occur. This is the purpose of core seating. When the core is seated, it is compressed in length and increased in diameter very slightly, moving the jacket out with it until the jacket contacts the core seating die walls. A very small amount of lead at the top of the core is pushed away from the jacket and compressed downward, collapsing the sink hole that must be created if the core has actually bonded to the jacket walls. (The core expands when heated, and shrinks when it cools, so if it is actually bonded to the jacket, there is no place for it to shrink away except to create a hole in the center.) The center hole is not truely centered and would be a source of inaccuracy (slight) if it were not compressed shut or purposefully made co-axial with the bullet by using a hollow point core seating punch. If you wish to make the core longer, as for making lead tips, simply swage a short second core. First seat the bonded core firmly, then insert the short core and seat it again on top of the bonded core. This may require a larger punch, which fits the die bore instead of the jacket bore.

The center hole is not truely centered and would be a source of inaccuracy (slight) if it were not compressed shut or purposefully made co-axial with the bullet by using a hollow point core seating punch. If you wish to make the core longer, as for making lead tips, simply swage a short second core. First seat the bonded core firmly, then insert the short core and seat it again on top of the bonded core. This may require a larger punch, which fits the die bore instead of the jacket bore.

The bonded core bullet can be drawn down further with no appreciable affect on accuracy compared to a non-bonded bullet. Therefore, the normal restrictions about reducing the bullet diameter to make other calibers by pushing it through a bullet reducing die may not apply to the bonded core bullet. (Usually a limit of about .005 to .006 inch reduction applies to non-bonded bullets.)

Cores can be pure lead, tin-lead alloys, or antimony-lead alloys, if the tin or antimony content is 3% or less. Pure lead makes the best performing bullets. Jacket materials can be copper, gilding metal, or various alloys of brass up to and including 30% zinc cartridge brass. Aluminum or steel jackets do not bond with this technique. Also, powder metals such as copper and tungsten do not bond without the presence of significant lead powder. The core length must be shorter than the jacket, to prevent it from running down the outside of the jacket. A lead tip cannot, be definition, be bonded since there is no jacket surrounding it. Therefore, you can make a lead tip bullet by seating two cores, one bonded and shorter than the jacket, and another swaged on top of the bonded core which is long enough to form the lead tip. The fact that the second short core is not bonded makes no practical difference.

The core length must be shorter than the jacket, to prevent it from running down the outside of the jacket. A lead tip cannot, be definition, be bonded since there is no jacket surrounding it. Therefore, you can make a lead tip bullet by seating two cores, one bonded and shorter than the jacket, and another swaged on top of the bonded core which is long enough to form the lead tip. The fact that the second short core is not bonded makes no practical difference.

Corbin also offers the HTO-2 electronic control heat treatment oven, which can be used for larger runs of bonded core bullets. Production runs of bonded core bullets are easy to make exactly the same, with the accurate control of temperature and even electrical heat from the embedded elements lining the oven cavity. The lining is a ceramic box about 3/8 inch thick, made of four folded sections with the heating element embedded in them. The HTO-2 may be purchased on the secure shopping cart or by e-mail. Prices are shown in the Corbin Price List.

Making Bonded Core Bullets