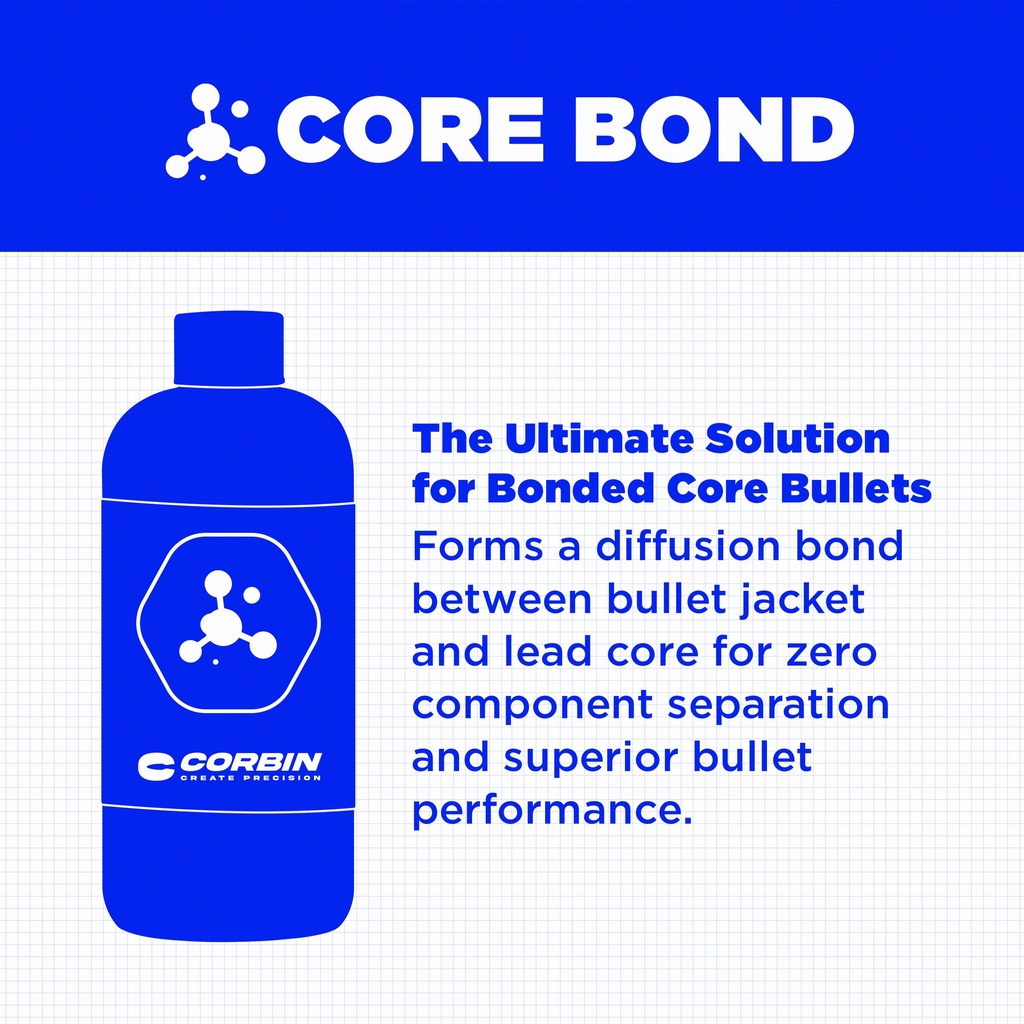

Corbin Core Bond Product Description

Corbin Core Bond is an essential adhesive designed specifically for securing bullet cores to jackets in swaging operations. This high-strength bonding agent ensures that your bullets maintain optimal performance and integrity, providing consistent accuracy and reliability in every shot.

Corbin Core Bond is the ultimate solution for high-performance bonded core bullets, backed by nearly 50 years of Corbin's expertise in bonding bullets. It is designed to lower the surface tension of lead and dissolve away oxides and carbonates, allowing the molten core to penetrate into the jacket material and form an inseparable bond.

Key Features:

- Superior Adhesion: Formulated to create a strong and durable bond between cores and jackets, preventing separation during firing.

- Enhanced Accuracy: Improves the ballistic performance of your bullets by maintaining the concentricity and alignment of the core and jacket.

- Easy Application: Comes with precise instructions for straightforward use, making it suitable for both novice and experienced reloaders.

- Versatile Compatibility: Works with various core and jacket materials, including lead, copper, and other common bullet components.

- High Temperature Resistance: Maintains its bond even under the high temperatures generated during firing, ensuring consistent performance.

Optimal Bonding Temperature: For the most effective results, a temperature of about 800 to 1000 degrees is required for the rapid melting of the lead core while the bonding flux is still present as a hot vapor. This ensures a strong and lasting bond between the core and the jacket. It is recommended to use a standard propane torch to accomplish this, inside the Corbin Heat Treatment Blocks. These ceramic blocks can be drilled to the diameter and depth required for your application, and can survive the heat necessary for bonded jacketed bullets.

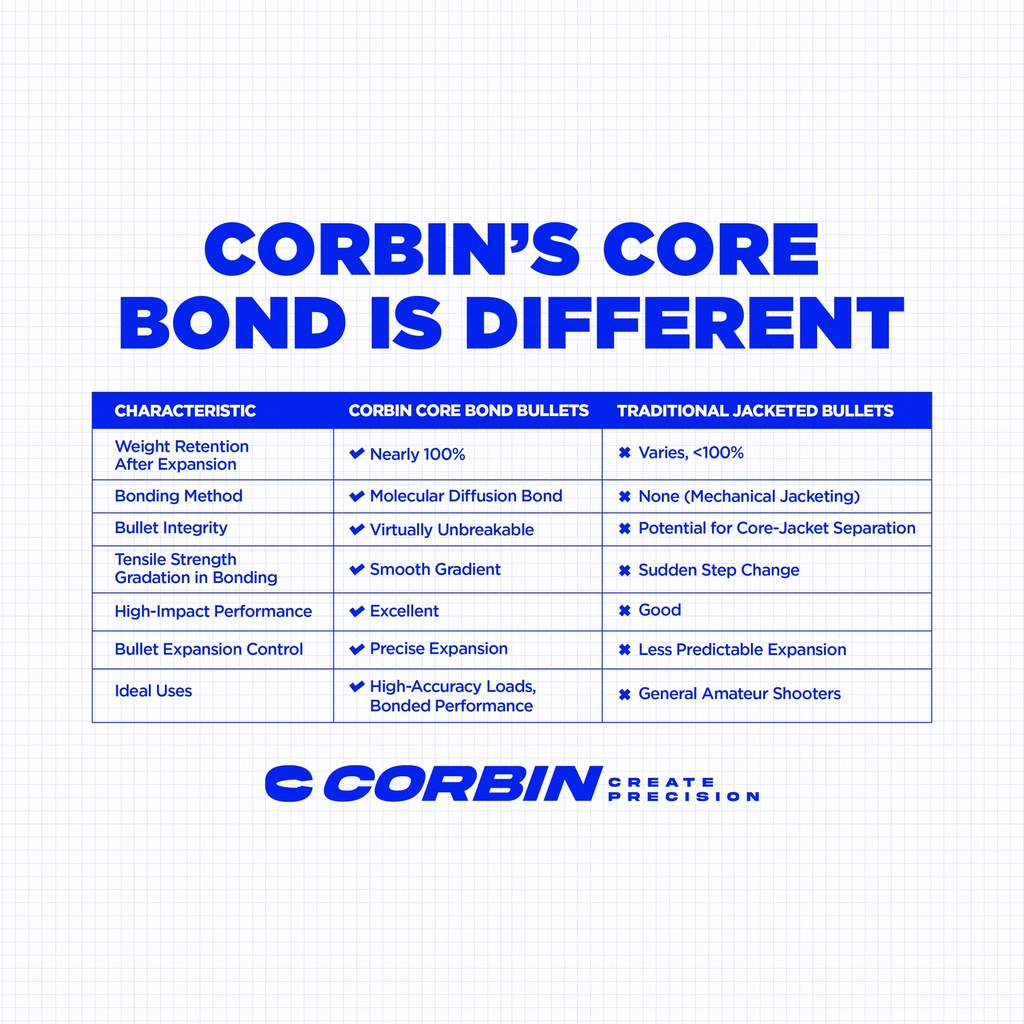

Making Bonded Core Bullets: Bonded core bullets, created using Corbin Core Bond, typically retain 90 to 100 percent of their weight after expansion and exhibit higher accuracy in high-acceleration loads because the core cannot slip or turn separately from the jacket. Corbin has perfected the diffusion bonding process, allowing the molecular migration of lead atoms into the copper jacket, ensuring a strong and reliable bond. This method provides a tensile strength gradient across the jacket-core boundary, reducing stress concentration and preventing core separation under high impact.

Unlike soldering or gluing, the diffusion bonding process allows lead atoms to penetrate the copper jacket, creating a smooth transition zone that withstands high stresses without peeling. The process involves heating the jackets with the cores and Core Bond applied, allowing the lead to melt and bond with the jacket material.

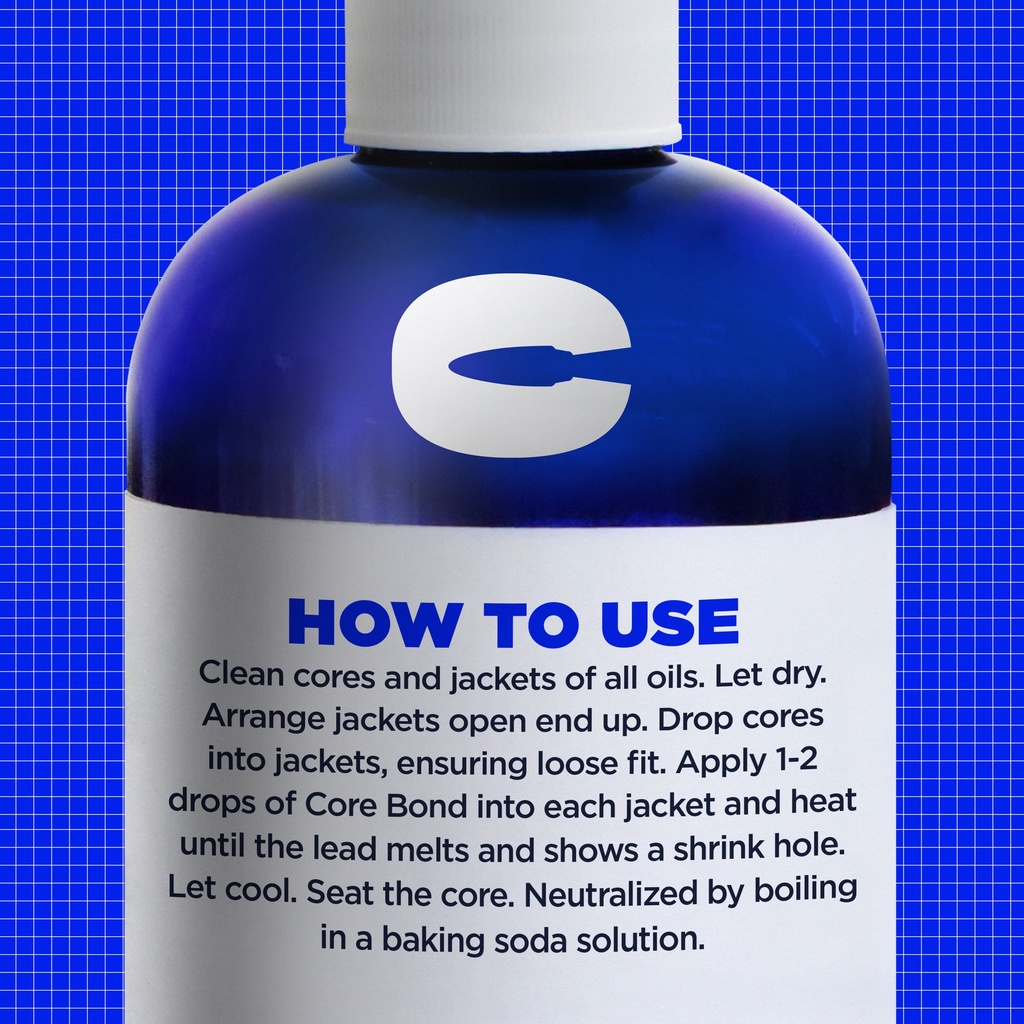

Usage Instructions:

- Prepare the Surfaces: Clean the core and jacket surfaces thoroughly to remove any dirt, grease, or oxidation.

- Apply Core Bond: Using the applicator, apply a thin, even layer of Core Bond to the core.

- Insert the Core: Place the core into the jacket and ensure it is properly seated.

- Heat the Jackets: Use a propane torch to heat the jackets so the lead melts inside them, ensuring even heating. Corbin recommends the Corbin Heat Treatment Block Kit (BL-KIT) to accomplish this.

- Allow to Cure: Let the Core Bond cure as per the recommended time to achieve maximum bond strength.

- Post-Bonding Process:

- After the bonding process is complete, examine the jackets and cores for any signs of improper bonding.

- Ensure the bonded cores have a shrink hole in the center if properly bonded, as the core expands when heated and shrinks when cooled. You want to see a concave dome shape, to ensure proper bonding has occurred.

- Swage the bonded cores just as if they had not been bonded. Bonding the core does not expand the jacket or remove voids which is necessary to ensure consistent projectiles.

- During core seating, compress the core in length and slightly increase its diameter, moving the jacket out until it contacts the core seating die walls.

- Use a hollow point core seating punch if making hollow point bullets, or seat a second core on top of the bonded core for lead tip bullets.

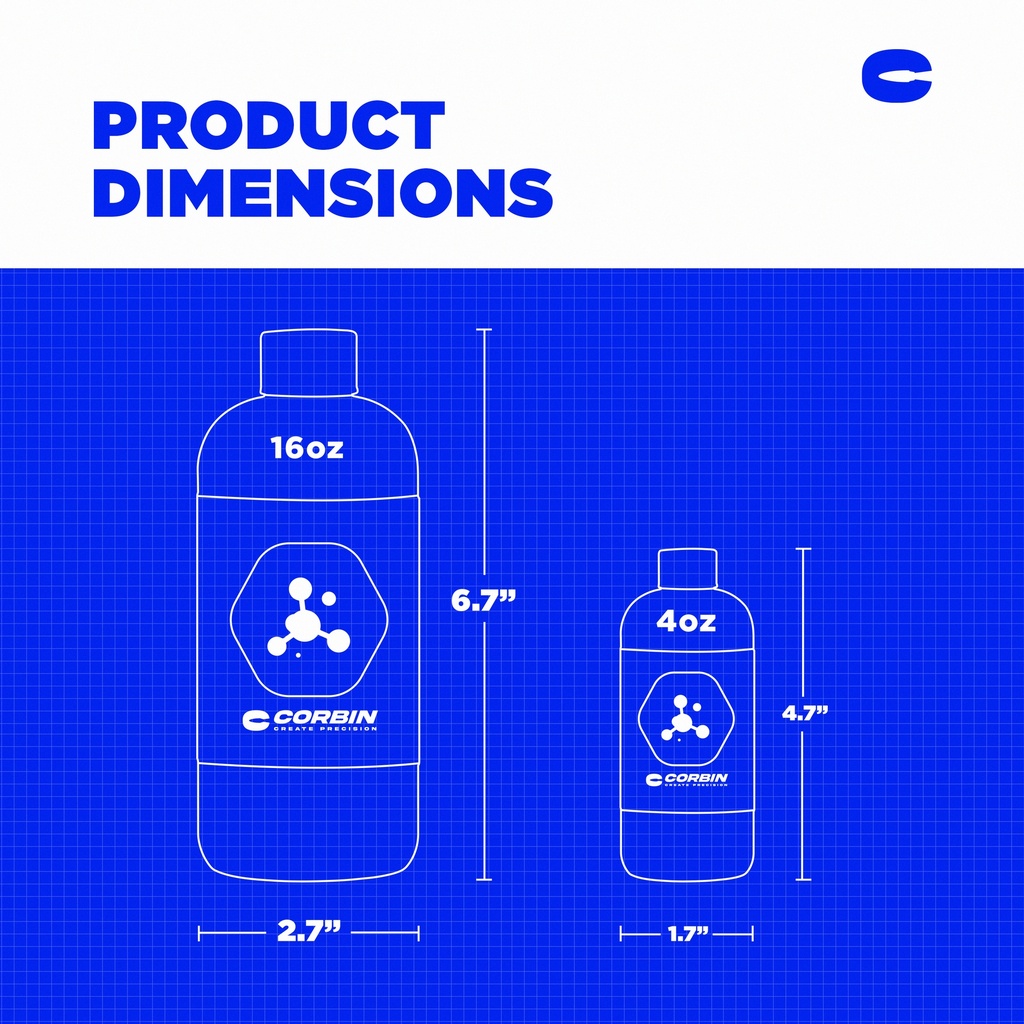

Packaging Options: Corbin Core Bond is available in various sizes to suit your reloading needs, whether you are a hobbyist or a professional swager. Choose from small tubes for occasional use or larger containers for high-volume production.

Invest in Corbin Core Bond to enhance the quality and performance of your swaged bullets, ensuring each one meets the highest standards of precision and durability.

- Main Purpose: To create high-performance bonded core bullets with nearly 100% weight retention upon impact.

- Unique Mechanism: Lowers the surface tension of lead and dissolves oxides and carbonates.

- Advanced Features: Prevents core separation and ensures reliable bullet integrity.

- Form Factor: Available in 2-ounce, pint, and gallon sizes.

- Application: Place two drops in the jacket, heat with a torch until the lead melts, and let it cool.

- Safety: Material Safety Data Sheet available for download.

Benefits

- Proven Expertise: Backed by nearly 50 years of Corbin's experience in bonding bullets.

- Effective Bonding: Ensures nearly 100% weight retention upon impact.

- Unparalleled Reliability: Creates an inseparable unit that delivers exceptional results.

- Ease of Use: Simple application process for thorough bonding.

- Safety: Material Safety Data Sheet available for added safety.

- Multiple Sizes: Available in various sizes to suit different needs.

| Material | Proprietary |

| Volume | 16 oz |