Corbin makes pellet swage dies for conventional .177 and .22 air guns as well as the full spectrum of diameters for specialty and precharged high-power air guns, including 50, 45 and 9mm rifles, .12, .14, 5mm (20 cal) and .25 caliber. Any caliber of air gun projectile can be made using Corbin equipment. The same tools can make a wide range of weight by adjustment.

| Generally, "pellets" refer to cylindrical projectiles which can be formed in a straight hole kind of die. The term "slugs" is commonly used to refer to smooth ogive, bullet shaped projectiles that do not have a reduced waist or a shoulder. Corbin does not produce tools to make the hour-glass shaped projectiles that can purchased "over the counter" through department stores. The problem with the hour-glass or "diablo" pellet is that it only contacts the bore in two narrow rings, front and rear, so any damage in shipping and handling may destroy the perfect air seal, causing differences in velocity from shot to shot depending on the location and amount of damage. This kind of design is usually produced on high speed "roller" devices rather than Corbin's style of precision swage dies. The "diablo" pellet is well suited to mass produced, general one-size-fits-all-models shooting. The easily compressed front and rear contact points, while fragile, do not introduce very much total bore friction. They can be pushed into various sizes of chambers and shot down different tolerances of bore with a nominal caliber size, usually .177 or .220, and the accuracy is acceptable for the casual air gun shooter. A straight sided pellet, on the other hand, must be made much more precisely to a specific diameter to provide low bore friction. It usually need to be made as a bore-riding design with a base that instantly expands to provide a good seal and rifling engagement. This provides vastly greater area than the diablo design for good bore alignment and air seal. The same amount of damage to a straight-sided pellet has very little effect on accuracy compared to an hour-glass shape. The precise diameter control and adjustable weight allow for far greater accuracy, provided the shooter matches the diameter to his gun, and is willing to experiment with weight instead of assuming whatever is mass produced hits the peak accuracy in every gun. Corbin makes the PRO-1-R PRO-SWAGE die to produce straight sided pellets in a reloading press, and the LSWC-1-S Lead Semi-Wadcutter style die to produce them quicker and with greater control in a Corbin S-Press. The larger Corbin CSP-2 Mega Mite press, and CHP-1 Hydro Press, use the LSWC-1-H die for the same job. |

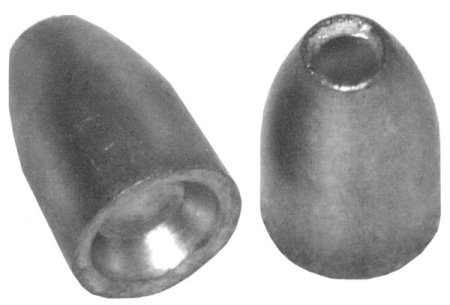

Another kind of air gun projectile is the smooth sided "slug". This projecile is ONLY made using Corbin presses because they are built to operate a PF-1-SP die, synchronized ejector style. For detailed information about this, and more information about pellets, check out the AIRGUN page. There are two ways to make this style of slug. One uses two dies and can make extremely light-for-caliber bullets that have a larger hollow cavity inside than the tip diameter. The other uses a single die and makes a finished bullet with one stroke, which can have a hollow tip (optional) that is the same or smaller diameter as the tip. To make the hollow shell style of slug, you would need the CSW-1-S Core Swage Die and a PF-1-SL die. First a lead core or piece of cut lead wire is swaged into an exact weight cylinder in the CSW-1-S die. The internal and external punches that fit into this die will have projecting "tips" on them. These projections create a hollow or cup base shape, as well as a huge hollow cavity for the nose. The resulting slug now looks like a cylinder with a shorter cavity in one end (base) and a big cavity in the other (nose). It is just slightly under finished diameter. For example. a .250 diameter slug would be around .249 or .2495 at this point. Then, in a second step, this hollow end slug would be pushed into the PF-1-SL die which has an ejector punch that is designed to fit into the nose cavity and push the bullet out by pressure against the partition left between the nose and base cavities. It can, in some special designs, be made shorter so it pushes against the bullet tip, once the tip has been nearly closed. The external or base punch matches the pre-formed cavity in the base end, to maintain that shape as the walls around the nose cavity are curved inward by the die walls. This style of slug, if cut in half along the axis, would be mostly hollow, with the nose cavity following the ogive shape. This is how the inside of the hollow cavity can be larger than the opening. Or the opening can be pushed almost completely closed. The point forming die normally does not use bleed holes to adjust the weight, since the core swage die already did that. The disadvantage of this design is that it takes two press strokes to finish a slug. The advantage is that the weight can be far less for the same caliber and ogive shape compared to a slug made in a single stroke. |

| The other kind of slug is one that can appear to be the same as the hollow 2-die style, but is made in a single die, with one stroke. The difference is that the hollow point, if you want one, can be no larger than the ejection punch. This is usually fine, and very popular, but it does set a slightly higher minimum weight for a given caliber and length. The kind of die used to make this slug is either the PF-1-SP (with bleed holes and synchronized ejector) or the PF-1-HP (same design in the larger -H style for the CSP-2 or Hydro Press). There is no equivalent die for a reloading press, since the design of the press must be configured to operate the synchronized ejector and allow for simultaneous weight adjustment with bleed holes in the die. For details about this style of die, please see Air Gun Projectiles page. For typical "standard" hollow point and caliber information regarding the slug design, please see Standard Slug Specs. |

| Home Page | Price List | E-Mail Sales | Site Map | New Products | Q&A | Terminology |

| Retirement | Specials | Real Estate | Software | How to swage | Classified Ads | Feedback |

| The Diana Model 10 used two pistons, one moving backward to cancel the momentum of the main piston compressing air behind the pellet, resulting in virtually no spring/piston recoil. The trigger could be adjusted for position, overtravel, pretravel, and two levels of trigger force. Both the front are rear sight had click adjustments. The front sight adjusts for profile width, and the rear for windage and elevation. The "barrel weight" is a rotating grip that covers the sights and forms a handle, used to "break" the barrel downward to cock the gun. The gun cannot be fired until this cover is rotated back under the barrel, after cocking. At 30 meters, the gun could put five 177 caliber pellets into a single ragged hole (the same might not always be said for the shooter). |

Start writing here...

About Corbin Air Gun Pellet Swaging