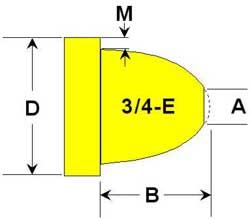

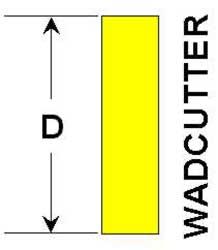

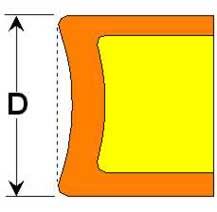

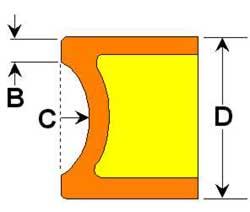

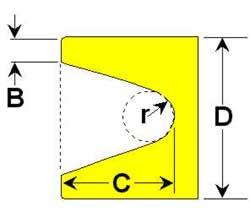

Bullet jacket lengths are relative to the lead coverage on typical pistol bullets. The full jacket is made for ogival-type bullets (no shoulder). When used for a semi-wadcutter style, the full jacket makes only the heaviest weights. The 3/4-jacket covers nearly the entire shank, leaving the nose exposed. It makes a medium to light weight ogival bullet (no shoulder), but a normal (medium) weight semi-wadcutter. The 1/2-jacket covers about half the normal weight bullet's shank. It can also make 3/4-jacket style (shank covered) in the light weights. A gas check only covers the base and a small portion of the shank. A Base Guard covers only the base but scrapes fouling out as it passes the sharp edge down the bore. 3/4-E Semi-Wadcutter (SWC) bullets are illustrated, using the same weight of core for all jackets.

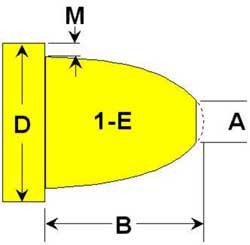

Compare these 1-E (one caliber, elliptical curve) ogive bullets with the 3/4-E. The typical handgun bullet weight and length generally works best with a 3/4-E ogive. The 1-E looks good on paper, but usually results in far too much volume of lead in the nose, making the bullet either too heavy, or nose heavy, in pistol weights. In rifle length bullets, the longer (1 caliber length along the axis) nose is a good match to the design. For some special purpose handgun loads, the 1-E can be satisfactory (usually only for the heaviest bullet weights).

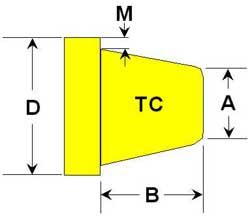

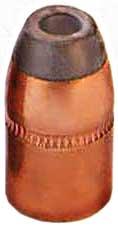

These Keith (named after the late Elmer Keith) or Truncated Conical Semi-Wadcutter style bullets are shown with the same weight, using different jackets. These are the so-called "Full", "3/4", and "1/2" jackets, then the gas check and Base Guard. Of these styles, the full jacket will usually be too heavy, and the 1/2-jacket and gas check may tend toward lead fouling. The Base Guard tends to scrape out the fouling for a cleaner bore, up to about 1200 to 1400 fps, in most guns, provided the diameter is a good fit to the bore.

These Keith Semi-Wadcutter style bullets are shown with the minimum practical weight for each jacket style. The minimum possible in a SWC design is where the lead just stops at the edge of the jacket, with the nose projecting. If the punch is driven down further, it simply crushes the jacket. To make lighter bullets in a simple SWC type die, you can use these techniques:

- Use a deep hollow point punch to remove some weight at the nose.

- Use a cup base punch to remove some weight at the base.

- Use a core material of low density, such as Corbin's polymer "bullet balls".

- Use a mixture of low and high density materials in the same bullet.

- Use powdered copper/tin mixture for the core instead of lead.

- Use a shorter nose design (minimum is a large HP with no nose projecting).

Button nose wadcutters (BWC) are classified in our system as another form of SWC design. Wadcutters simply have less nose (or no nose) projecting from the end. They still have lead just at the edge of the jacket, if one is used, and are made in the same die as a SWC, by changing to the proper nose punch. A TWC (target wadcutter) does not have the tiny "button" of lead for a nose, and is flat across the end. It has a small ring depressed into the face, like a target. The wadcutter designs are the minimum weight in the jacket without going to a hollow point or cup base design. Note that a cup base generally does not work on a gas check, and never works on a Base Guard because of the method of attaching the copper disk.

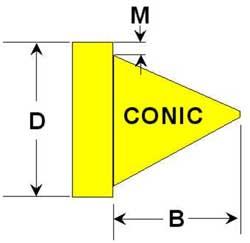

Semi-wadcutter nose shapes (standard) from left to right: Target Wadcutter (TWC), Button Nose Wadcutter (BWC), Conical, Keith, Auto-Loader (AL), 3/4-E, 1-E. (Click the picture for a larger image). Photo by D.R. Corbin, of .452 Bullets.

Semi-wadcutter nose shapes (standard) from left to right: Target Wadcutter (TWC), Button Nose Wadcutter (BWC), Conical, Keith, Auto-Loader (AL), 3/4-E, 1-E. (Click the picture for a larger image). Photo by D.R. Corbin, of .452 Bullets.

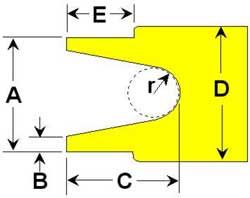

Semi-Wadcutter Shapes Wadcutter Shapes To design a special semi-wadcutter style bullet, print one of the diagrams listed below, and put in the dimensions you desire. Then send us a copy. In order to make the bullet, we must machine a punch with the reverse shape in the tip. Some designs can be too fragile or nearly impossible to machine. Others may have difficulty with trapped air or lube, or may not release the bullet nose easily enough. We can help sort out these problem areas in designs, and suggest changes that would solve them while accomplishing whatever it is you want the bullet to do. |

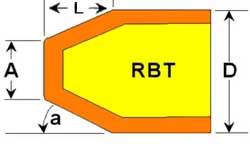

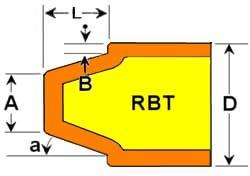

| Bullet Bases Bullet Bases can be made in the flat (FB), dish base (DB), cup base (CB), hollow base (HB), heel base (no abbreviation used), boattail (BT), and the superior rebated boattail (RBT). Corbin does not make the standard BT but only the RBT, which offers about 15% better accuracy due to less muzzle blast induced dispersion, better barrel life, less gas cutting in some loads, and far longer tooling life.

|

Rifle Nose Shapes

Spitzers or "tangential ogive" bullets are a special case of secant ogives where the angle joining the nose and the shank is zero. That is, all bullet noses that utilize a section or arc from a circle as the major shape of the ogive are secants, but we reserve the tangent or spitzer name for the one special case of zero angle of junction.

Spitzers or "tangential ogive" bullets are a special case of secant ogives where the angle joining the nose and the shank is zero. That is, all bullet noses that utilize a section or arc from a circle as the major shape of the ogive are secants, but we reserve the tangent or spitzer name for the one special case of zero angle of junction.

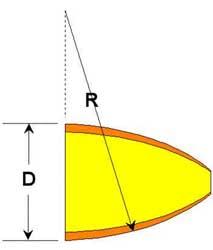

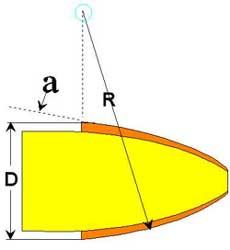

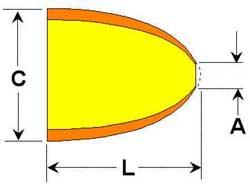

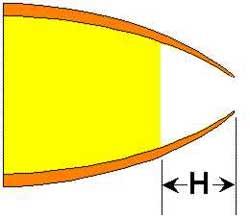

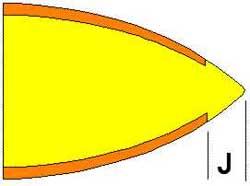

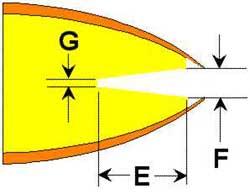

The spitzer bullet is constructed on paper by drawing two arcs with a compass, the radius of each being identical, and being specified in "calibers". The two arcs are drawn so that they start at the shank and curve toward the center line of the bullet, crossing or at least touching the center line. The origin of the radius is located on a line perpindicular to the centerline and even with the end of the shank. A spitzer is designated in calibers of radius, such as 2-S, 6-S, or 10-S. This means that the length of the radius of the ogive arc is 2 calibers, 6 calibers, or 10 calibers. Since the arc has to go from the shank to the centerline, it isn't possible to make a spitzer with less than 0.5 caliber radius (which is a round ball nose and is identical to a 1/2-E eliptical ogive).

A spitzer is designated in calibers of radius, such as 2-S, 6-S, or 10-S. This means that the length of the radius of the ogive arc is 2 calibers, 6 calibers, or 10 calibers. Since the arc has to go from the shank to the centerline, it isn't possible to make a spitzer with less than 0.5 caliber radius (which is a round ball nose and is identical to a 1/2-E eliptical ogive).

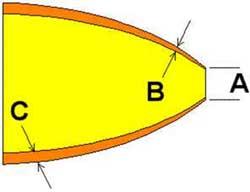

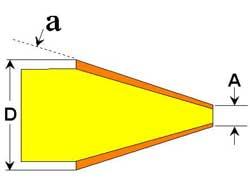

Tangential ogives are the most popular and common shape, and they are mathmatically easy to describe and to create on paper. The one thing people often forget is the jacket thickness, which prevents the tip of the bullet from being closed to a sharp point. If the jacket has .035 inch thick walls, then the absolute minimum tip closure will be 0.070 inches across, and more likely it will be 0.091 to 0.105 inches because of the pressure that smaller closure would require and the strength of the ejection pin needed to push the bullet back out of the die. Most rifle bullets use a 6-S ogive because it gives the best range of weight to length, until the caliber becomes large enough to make the weight excessive. Usually a 4-S or shorter radius is used for calibers of .375 and larger, until we get to the very large and heavy .512 (50 Browning Machine Gun) bullet, which is used in guns that can handle 600-900 grain bullets. This lets us use a longer ogive radius again, from 6-S to 10-S being typical.

Most rifle bullets use a 6-S ogive because it gives the best range of weight to length, until the caliber becomes large enough to make the weight excessive. Usually a 4-S or shorter radius is used for calibers of .375 and larger, until we get to the very large and heavy .512 (50 Browning Machine Gun) bullet, which is used in guns that can handle 600-900 grain bullets. This lets us use a longer ogive radius again, from 6-S to 10-S being typical. The larger the ogive number for a spitzer, the more pointed the bullet becomes. It also becomes longer in a non-linear manner. The greatest changes in length take place in the low end, and become less and less as the same amount of change takes place in larger numbers. That is, a bullet that goes from 2-S to 4-S becomes significantly longer and more pointed. Going from 4-S to 6-S makes a noticable but smaller difference. From 6-S to 8-S is a moderate change, and from 8-S to 10-S is less so. But from 10-S to 12-S, you can barely tell the difference, and for longer ogives, the only noticable difference is at the very tip, and only if the meplat or end is very sharp.

The larger the ogive number for a spitzer, the more pointed the bullet becomes. It also becomes longer in a non-linear manner. The greatest changes in length take place in the low end, and become less and less as the same amount of change takes place in larger numbers. That is, a bullet that goes from 2-S to 4-S becomes significantly longer and more pointed. Going from 4-S to 6-S makes a noticable but smaller difference. From 6-S to 8-S is a moderate change, and from 8-S to 10-S is less so. But from 10-S to 12-S, you can barely tell the difference, and for longer ogives, the only noticable difference is at the very tip, and only if the meplat or end is very sharp.

Corbin offers spitzers in 6-S for most calibers as standard. Ogives of .5, 1, 2, 4, 6, 8, 10, and 12 can also be made, and for longer ogive, we recommend the ULD or 14-caliber secant with a 0.014 offset from tangent. Secant ogives are just like tangents except the junction of the ogive and shank makes an angle other than zero. Therefore, it is not enough to specify the secant ogive radius in calibers. You must also define either the angle of attachment, or the distance that the ogive would have to be moved sideways in order to make it meet tangent with the shank.

Secant ogives are just like tangents except the junction of the ogive and shank makes an angle other than zero. Therefore, it is not enough to specify the secant ogive radius in calibers. You must also define either the angle of attachment, or the distance that the ogive would have to be moved sideways in order to make it meet tangent with the shank.

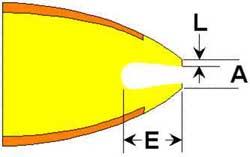

A secant ogive has a bit of a discontinuity or non-smooth change from ogive curve to shank. The idea is to join a long ogive radius to the shank so that the axial length (along the centerline) can be made shorter than if the entire arc from tip to shank were joined tangent to the shank. We "slide the ogive" over to one side and chop off a bit of the curve, in other words. The reason for doing this is to try to fool Mother Nature into thinking that there is a smooth ogive, without any discontinuity, and get a more streamlined curve that isn't so long as it would be in a spitzer. That makes the bullet closer to a practical weight, because the over-all length is shorter. A 14-S secant with .014 offset can be as short as a 10-S tangent, depending on the relative size of the meplats. If the angle is increased enough, the secant starts to generate a secondary shock wave from the disrupted air flow, and the advantage of having a longer ogive curve is lost. There is a narrow practical range where a secant works well for supersonic bullets, and not much reason to use it at all for subsonic bullets.

The reason for doing this is to try to fool Mother Nature into thinking that there is a smooth ogive, without any discontinuity, and get a more streamlined curve that isn't so long as it would be in a spitzer. That makes the bullet closer to a practical weight, because the over-all length is shorter. A 14-S secant with .014 offset can be as short as a 10-S tangent, depending on the relative size of the meplats. If the angle is increased enough, the secant starts to generate a secondary shock wave from the disrupted air flow, and the advantage of having a longer ogive curve is lost. There is a narrow practical range where a secant works well for supersonic bullets, and not much reason to use it at all for subsonic bullets. Pushing the design to the edge of practicality is a mistake in most cases, if you are not positive about the atmospheric pressure and humidity at the time of firing and design for it. A bullet that is optimized for low drag at normal air density may develop a secondary shock wave if the density increases slightly, spoiling any plans to get lower drag than a more normal bullet design. Worse, the conditions might be "on the edge" of switching back and forth, where a tiny change in pressure generates a shock wave from the ogive-shank junction over just part of the flight, depending on velocity as well as shifts in weather, and your groups go all over the target. Better to sacrifice a little "paper advantage" and work well within the area where such small changes in conditions would have no effect.

Pushing the design to the edge of practicality is a mistake in most cases, if you are not positive about the atmospheric pressure and humidity at the time of firing and design for it. A bullet that is optimized for low drag at normal air density may develop a secondary shock wave if the density increases slightly, spoiling any plans to get lower drag than a more normal bullet design. Worse, the conditions might be "on the edge" of switching back and forth, where a tiny change in pressure generates a shock wave from the ogive-shank junction over just part of the flight, depending on velocity as well as shifts in weather, and your groups go all over the target. Better to sacrifice a little "paper advantage" and work well within the area where such small changes in conditions would have no effect. Eliptical ogives have a constantly changing radius about two loci or focal points, so you can't specify them with a single ogive radius figure. The best way to describe them quickly and positively is by the axial length, or distance in calibers they extend above the shank along the center line of the bullet.

Eliptical ogives have a constantly changing radius about two loci or focal points, so you can't specify them with a single ogive radius figure. The best way to describe them quickly and positively is by the axial length, or distance in calibers they extend above the shank along the center line of the bullet.

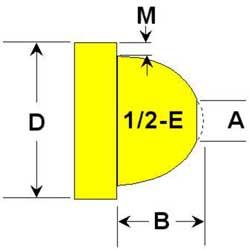

However, this method means you have to be aware that the changes in length are huge when you go from a 1 to a 2 caliber. The smallest possible eliptical ogive is 1/2 or 0.5-E. That is a circle or ball, because the length of the nose is half the caliber, or the exact radius of the bullet. Going up to a 3/4 or .75-E nose gives us the typical round nose handgun bullet, which is not really "round" but is "half a prolate spheroid". This jargon means you could form a ball, squash it so that it looks a little like a round-tipped football (prolate as opposed to the other direction which is doughnut-like oblate), and cut it in in half at the middle, so you have half of the football, a kind of rounded-end cone. A 1-E ogive is a full caliber long in the nose. If you had a 1-inch diameter shell, the nose would be 1 inch long, same as the caliber. In contrast, if you changed the shape to 3/4-E it would only be 0.75 inches long, and 1/2-E would only be 0.5 inches long. Some people want to make a 2-E ogive, but if you draw it out to scale you soon realize that this is a bullet that is all nose in any practical weight for small arms ammo. For instance, a .458 rifle bullet with a 2-E nose has a nose that is 0.916-inches long! To be reasonably balanced, the nose and base need to be somewhat in the same general length range, and certainly more than a caliber for the shank alone. You'd have over 1.83 inch long bullets in .458, for instance. Want to shoot a 650-700 grain .458 from your favorite .45-70 rifle? Will it even feed or chamber?

A 1-E ogive is a full caliber long in the nose. If you had a 1-inch diameter shell, the nose would be 1 inch long, same as the caliber. In contrast, if you changed the shape to 3/4-E it would only be 0.75 inches long, and 1/2-E would only be 0.5 inches long. Some people want to make a 2-E ogive, but if you draw it out to scale you soon realize that this is a bullet that is all nose in any practical weight for small arms ammo. For instance, a .458 rifle bullet with a 2-E nose has a nose that is 0.916-inches long! To be reasonably balanced, the nose and base need to be somewhat in the same general length range, and certainly more than a caliber for the shank alone. You'd have over 1.83 inch long bullets in .458, for instance. Want to shoot a 650-700 grain .458 from your favorite .45-70 rifle? Will it even feed or chamber?

The 1-E ogive is very much a standard for black powder cartridge rifles, paper patch bullets, and modern big game jacketed bullets used in Africa. It is a good shape for hunting, although not particularly aerodynamic for long range shooting. The 3/4-E is standard for handgun, and the 1-E is standard for rifle, but other shapes of eliptical ogives can be made to custom order. Spire point bullets are made with two straight lines, joined to the shank at a specified angle (which is typically 9 to 12 degrees). The spire shape is like a pencil tip or "church spire" in shape. Do not confuse spire and spitzer. The spitzer is a curve, an arc from a circle. The only curve in a spire is a possible tiny radius joining the shank to the ogive, which is probably incidental to the polishing process and not by design.

Spire point bullets are made with two straight lines, joined to the shank at a specified angle (which is typically 9 to 12 degrees). The spire shape is like a pencil tip or "church spire" in shape. Do not confuse spire and spitzer. The spitzer is a curve, an arc from a circle. The only curve in a spire is a possible tiny radius joining the shank to the ogive, which is probably incidental to the polishing process and not by design.

Spire point bullets are ballistically equivalent to spitzers of the same axial ogive length. They take a straighter path from shank to tip, and cut off a small amount of volume by doing so. Therefore, a spire point bullet can be slightly lighter for the same over-all length. There is no particular disadvantage other than the need to maintain a smaller angle of tip for bullets that will be shot at supersonic speeds, to avoid generating a secondary shock wave at the ogive-shank junction.

Bullet Tip Styles

|

The dish base (DB) design is generally used to provide a very slight outward expansion of the bullet during firing, by vectoring a small component of the gas pressure at a slight angle to the bullet centerline. This can help "seal" the bore when the bullet is used in undersize or unknown size barrels and prevent gas cutting. It seems to have little or no effect on accuracy other than improving it in an oversize barrel. It can also be used in a rimfire 6mm jacket to help apply more localized pressure, during core seating, to the edge of the jacket and thus expand it better, removing as much of the prior firing pin dent as possible. Dish base bullets have a slight concavity, going from edge to edge without a margin, and typically using a radius of several times the diameter to produce a very shallow curve, usually less than 1/10 of the caliber.

The dish base (DB) design is generally used to provide a very slight outward expansion of the bullet during firing, by vectoring a small component of the gas pressure at a slight angle to the bullet centerline. This can help "seal" the bore when the bullet is used in undersize or unknown size barrels and prevent gas cutting. It seems to have little or no effect on accuracy other than improving it in an oversize barrel. It can also be used in a rimfire 6mm jacket to help apply more localized pressure, during core seating, to the edge of the jacket and thus expand it better, removing as much of the prior firing pin dent as possible. Dish base bullets have a slight concavity, going from edge to edge without a margin, and typically using a radius of several times the diameter to produce a very shallow curve, usually less than 1/10 of the caliber. The cup base (CB) is typical of paper-patched lead bullets, but can also be used with a jacketed bullet. It has a radius cavity that is less than half a caliber deep, starting after a margin of from .010 to 0.030 inches (typically about 0.020) from the edge of the bullet. The margin gives the bullet edge greater resistance to expansion at the muzzle, and is designed for the range of muzzle pressure expected. Thicker margins work best with short barrels and high pressure loads, thin margins work best with longer barrels and lower pressures. The problem with a very thin margin and a high pressure at the muzzle is that at the moment the barrel is "uncorked" by the bullet passing the muzzle, the pressure is supported momentarily only by the thin walls of the bullet base. The pressure can expand the base excessively, even to the point of cracking it apart.

The cup base (CB) is typical of paper-patched lead bullets, but can also be used with a jacketed bullet. It has a radius cavity that is less than half a caliber deep, starting after a margin of from .010 to 0.030 inches (typically about 0.020) from the edge of the bullet. The margin gives the bullet edge greater resistance to expansion at the muzzle, and is designed for the range of muzzle pressure expected. Thicker margins work best with short barrels and high pressure loads, thin margins work best with longer barrels and lower pressures. The problem with a very thin margin and a high pressure at the muzzle is that at the moment the barrel is "uncorked" by the bullet passing the muzzle, the pressure is supported momentarily only by the thin walls of the bullet base. The pressure can expand the base excessively, even to the point of cracking it apart. The hollow base (HB) bullet typically has a conical or combination radius and conical cavity shape, but it may be made with a truncated conical cavity. The difference between hollow and cup base is the depth. Hollow bases are almost always made a half caliber or deeper. This shifts the weight considerably forward on the bullet. Hollow bases are generally impractical to use with jacketed bullets, as the jacket will be penetrated and cracked by the amount of force needed to draw it into this conical shape in a simple one stroke operation. The HB shape is typically used on lead handgun bullets, or on large calibers where the weight would be excessive if the bullet were very long with a solid base. Shotgun slugs, airgun pellets, and other projectiles that need to conform to the bore easily, or need to have the stability guaranteed over a moderate to short range, often are made in a hollow base design.

The hollow base (HB) bullet typically has a conical or combination radius and conical cavity shape, but it may be made with a truncated conical cavity. The difference between hollow and cup base is the depth. Hollow bases are almost always made a half caliber or deeper. This shifts the weight considerably forward on the bullet. Hollow bases are generally impractical to use with jacketed bullets, as the jacket will be penetrated and cracked by the amount of force needed to draw it into this conical shape in a simple one stroke operation. The HB shape is typically used on lead handgun bullets, or on large calibers where the weight would be excessive if the bullet were very long with a solid base. Shotgun slugs, airgun pellets, and other projectiles that need to conform to the bore easily, or need to have the stability guaranteed over a moderate to short range, often are made in a hollow base design. The heel base bullet is made to fit into the cartridge case up to the base shoulder, and is used in certain very old calibers where the original size of the bullet diameter was the same as the chamber. Conversions of blackpowder cap and ball revolvers to shoot cartridges meant that the chambers usually fitted the ball or bullet diameter, so inserting a cartridge meant the cartridge case diameter needed to be the same. Later, when guns were manufactured as cartridge revolvers, rather than using existing cylinders or stock tooling and supplies originally designed for cap and ball guns, the cases were made larger than the bullet diameter so that the bullet lubricant grooves would be inside the case, protected from dirt.

The heel base bullet is made to fit into the cartridge case up to the base shoulder, and is used in certain very old calibers where the original size of the bullet diameter was the same as the chamber. Conversions of blackpowder cap and ball revolvers to shoot cartridges meant that the chambers usually fitted the ball or bullet diameter, so inserting a cartridge meant the cartridge case diameter needed to be the same. Later, when guns were manufactured as cartridge revolvers, rather than using existing cylinders or stock tooling and supplies originally designed for cap and ball guns, the cases were made larger than the bullet diameter so that the bullet lubricant grooves would be inside the case, protected from dirt. Boattail base (BT) bullet dies are not made by Corbin for a number of technical reasons, primarily that there is no point in making something that isn't as good as the RBT design has proven itself to be over the decades. But most mass produced bullets including military designs still use the old boattailed design, as it is easier to keep on doing it than to convince people there is anything better (and, the tooling is paid for, the advertising has been written for years, and there is no upside to the manufacturer so long as no one else does it either).

Boattail base (BT) bullet dies are not made by Corbin for a number of technical reasons, primarily that there is no point in making something that isn't as good as the RBT design has proven itself to be over the decades. But most mass produced bullets including military designs still use the old boattailed design, as it is easier to keep on doing it than to convince people there is anything better (and, the tooling is paid for, the advertising has been written for years, and there is no upside to the manufacturer so long as no one else does it either). Rebated Boattail (RBT) bullets were first introduced in mass production by the Finnish Ammunition concern of Lapua (controlled by the Finnish government). The design provided a solution to the problem of muzzle gas focusing itself in a ball in front of the emerging bullet, which takes place with a boattail design. Flat bases, and rebated boattail, deflect the laminar flow of muzzle gas that wishes to follow the smooth outline of the bullet and then break up right in front of it. The gas is forced to flow off in a ring, with a clear area in the center through which the bullet passes. This can make up to 15% improvement in the dispersion or group size.

Rebated Boattail (RBT) bullets were first introduced in mass production by the Finnish Ammunition concern of Lapua (controlled by the Finnish government). The design provided a solution to the problem of muzzle gas focusing itself in a ball in front of the emerging bullet, which takes place with a boattail design. Flat bases, and rebated boattail, deflect the laminar flow of muzzle gas that wishes to follow the smooth outline of the bullet and then break up right in front of it. The gas is forced to flow off in a ring, with a clear area in the center through which the bullet passes. This can make up to 15% improvement in the dispersion or group size. The flat base (FB) is, of course, the most common and is the "default" design when no other design is mentioned for a jacketed bullet. With a lead bullet, the Base Guard (BG) and the flat base (FB) are ballistically identical: they perform the same way and you can use a BG punch without the copper disk with no ill effect (a tiny bump appears in the exact center of the base). However, the BG design will scrape fouling from the bore, whereas an ordinary flat base lead bullet has no capability to do this. A gas checked base is less effective at cleaning the bore than the BG base.

The flat base (FB) is, of course, the most common and is the "default" design when no other design is mentioned for a jacketed bullet. With a lead bullet, the Base Guard (BG) and the flat base (FB) are ballistically identical: they perform the same way and you can use a BG punch without the copper disk with no ill effect (a tiny bump appears in the exact center of the base). However, the BG design will scrape fouling from the bore, whereas an ordinary flat base lead bullet has no capability to do this. A gas checked base is less effective at cleaning the bore than the BG base. The Open Tip (OT) is just the result of seating the core below the jacket. This is sometimes called a hollow point but that is not the correct name for it. You can have an open tip with a hollow point, a lead tip with a hollow point, an open tip without a hollow point, or a lead tip without a hollow point. But you can not have a lead tip with an open tip. This is a contradiction.

The Open Tip (OT) is just the result of seating the core below the jacket. This is sometimes called a hollow point but that is not the correct name for it. You can have an open tip with a hollow point, a lead tip with a hollow point, an open tip without a hollow point, or a lead tip without a hollow point. But you can not have a lead tip with an open tip. This is a contradiction. Lead Tip (LT) bullets, also called "soft points", are made by seating the core so it is longer than the jacket, or at least so that when the ogive is formed the lead extrudes out of the jacket to some extent. The core seating punch might be a close fit near the jacket mouth in this latter case. Larger lead tips usually require a punch that is sized to fit the die bore, rather than the inside of the jacket.

Lead Tip (LT) bullets, also called "soft points", are made by seating the core so it is longer than the jacket, or at least so that when the ogive is formed the lead extrudes out of the jacket to some extent. The core seating punch might be a close fit near the jacket mouth in this latter case. Larger lead tips usually require a punch that is sized to fit the die bore, rather than the inside of the jacket. Open Tip Hollow Point (OTHP) tips are made by using a special core seating punch that fits the jacket ID, but has a conical projection. The OTHP core seating punch forms the cavity in the core while it is seating the core in the jacket.

Open Tip Hollow Point (OTHP) tips are made by using a special core seating punch that fits the jacket ID, but has a conical projection. The OTHP core seating punch forms the cavity in the core while it is seating the core in the jacket. Lead Tip Hollow Point (LTHP) tips are made by using a core seating punch that fits the die bore, rather than the jacket ID, and also has a conical projection on the end. The LTHP core seating punch forms the cavity in the lead while it compresses the lead core into the jacket.

Lead Tip Hollow Point (LTHP) tips are made by using a core seating punch that fits the die bore, rather than the jacket ID, and also has a conical projection on the end. The LTHP core seating punch forms the cavity in the lead while it compresses the lead core into the jacket. The cavity shape on any hollow point should be made with a tapered punch. Even a few degrees of taper is enough to allow the punch to be removed more easily from the bullet, with less sticking. A straight wall cavity is possible, but without lubrication on every pass (applied with the fingers on the punch) such a punch will be very likely to grip the bullet and require some effort to pull the bullet free. Because the bullet is in the die, and is expanded firmly against the die walls, while the seating punch is "external" and is retracted out of the die on each stroke, using less lube on the outside of the bullet and slightly more pressure when seating will often increase the grip between the die and the bullet sufficiently so that a straight HP punch will have less grip and can be removed from the bullet on the down stroke of the press. Try that, if the bullet tends to come out of the die, stuck to the HP punch.

The cavity shape on any hollow point should be made with a tapered punch. Even a few degrees of taper is enough to allow the punch to be removed more easily from the bullet, with less sticking. A straight wall cavity is possible, but without lubrication on every pass (applied with the fingers on the punch) such a punch will be very likely to grip the bullet and require some effort to pull the bullet free. Because the bullet is in the die, and is expanded firmly against the die walls, while the seating punch is "external" and is retracted out of the die on each stroke, using less lube on the outside of the bullet and slightly more pressure when seating will often increase the grip between the die and the bullet sufficiently so that a straight HP punch will have less grip and can be removed from the bullet on the down stroke of the press. Try that, if the bullet tends to come out of the die, stuck to the HP punch.

Bullet Designs