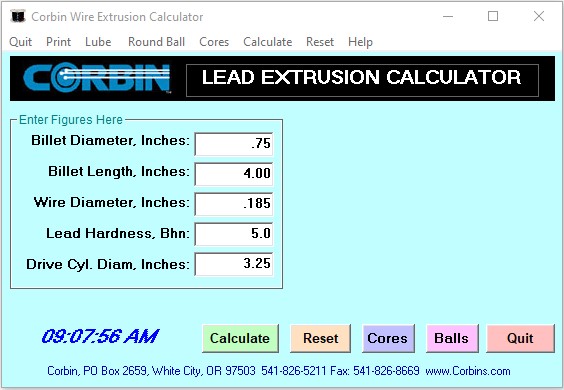

The Powder Metals, Lead Wire Extrusion is a program that calculates various parameters for lead wire extrusion and powdered metal cores. It helps you determine the length, weight, and volume of lead wire that can be extruded from a given diameter of lead billet. It also calculates the compressed length and effective density of powdered metal cores.

The program provides feedback if impractical values are entered, and self-corrects back to a reasonable number. The screens can be printed on any Windows-compatible printer. Density is given in pounds per cubic inch, and displayed in grams per cubic centimeter as well.

The extruder functions are based on certain assumptions about the amount of friction and resistance caused by moving the lead through a certain diameter extrusion die. In a practical system, there are variations in resistance due to die design, smoothness, lubrication, and temperature. Therefore, the program provides an adjustment factor called "lubricant efficiency" which adjusts the amount of resistance assumed, and changes the pressure for a given hardness and diameter of wire extruded with a given size of cylinder from a certain length and diameter of billet.

The normal setting for lube efficiency is "10", but it can be set from 1 to 100 to bring the results in line with experience from a given machine. To predict extruder size and pressure with reasonable margin of safety, always use the lower efficiency settings until you know for certain that your extruder does, in fact, allow lower pressures.

Powdered metals are usually poured into a core swage die or jacketed bullet "cup" (the jacket itself) and then compressed. The volume and effective density of the core will change with compression. The basic metal density itself will always be higher than the effective density, since small amounts of space exist between particles of the powder which are not present in the solid form of the metal (or other powder).

The program asks for the basic material density of the solid, and then asks for the diameter of the core and the amount of compression as a percentage of original "as poured" volume. When you pour a powder into a die or jacket, it "stacks up" in a long column. Then, a punch is used to compress this column into the jacket or die, shortening the column. The ratio of the original column to the compressed core length is this percentage. A core cannot be compressed 100% because that would mean it went from some measurable length to zero and the means to do that are beyond the normal realm of bullet manufacturing. A typical compression might be between 20 and 50 percent. The core weight remains the same as the original volume of powder, but the density is increased as the length is decreased. The program gives you these figures.

The combination of materials, whether they are powders or solids melted together, or simply putting one after another into a die or jacket as solid bits, results in a net effective density which would be the same as a single material of some type. The program lets you calculate two or three different materials in various ratios from 0 to 100 percent each, of different densities, in order to show this effective density. Zero percent means that there is none of that material, so it is taken out of the equation completely. One hundred percent means no other materials are present. Anything between these two numbers gives a valid calculation of effective density for two or three materials in one core.

Just plug the flash drive into a matching USB port, open the application in the respective folder, and the menu will appear. With new Windows updates some programs may have technical issues as a result of certain Visual Basic Files that are no longer provided by default that these programs require. There is a troubleshooting folder loaded onto the USB in case your specific machine has issues.

- Main Purpose: Calculates parameters for lead wire extrusion and powdered metal cores

- Compatibility: Suitable for various hydraulic drive cylinders and lead billet sizes

- Features: Multiple calculation windows for length, weight, volume, and effective density

- Additional Info: Provides an adjustment factor called "lubricant efficiency"

Benefits

- Precision: Accurate calculations for lead wire extrusion and powdered metal cores.

- Versatility: Suitable for a wide range of hydraulic drive cylinders and lead billet sizes.

- Ease of Use: User-friendly interface with self-correcting features for illogical or extreme values.