The DC-1003 paper patch bullet design program has four sections, each reached from the main menu window. These are:

- Bullet diameter calculations.

- Bullet weight calculations.

- Two-Part Bullet calculations.

- Cost per bullet calculations.

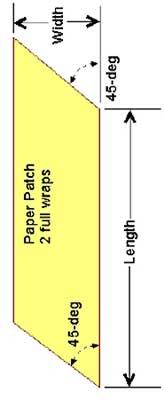

The diameter calculation assumes you have a gun, some paper, and know the weight of bullet you wish to shoot. If you have the gun, you can determine the groove to groove diameter and rifling depth, and if you have the paper, you can measure its thickness. Armed with this information, you can decide what shape of bullet you want to try, what material you wish to use for the bullet, and then calculate the length, proper diameter for either breech or muzzle loading with paper patch, the length and width of the patch for a typical 2-wrap patch, and get a good idea of the spin rate or twist that the bullet would require for stability.

The diameter calculation assumes you have a gun, some paper, and know the weight of bullet you wish to shoot. If you have the gun, you can determine the groove to groove diameter and rifling depth, and if you have the paper, you can measure its thickness. Armed with this information, you can decide what shape of bullet you want to try, what material you wish to use for the bullet, and then calculate the length, proper diameter for either breech or muzzle loading with paper patch, the length and width of the patch for a typical 2-wrap patch, and get a good idea of the spin rate or twist that the bullet would require for stability.

The program also gives you the shank and nose length, and the volume of lead used for each bullet, based on the material density, diameter, and the depth and width of hollow base (if any) and flat tip or meplat (if any), in addition to calculating the proper bullet diameter and the resulting bullet length.

The bullet weight calculations assume you have a gun already, and can obtain the basic barrel information such as rifling depth and bore size, and twist rate. It will then calculate the weight of bullet which should best stabilize in this barrel given a specific shape which you can change to compare with other bullets. The assumption is that you will probably have the gun, and want to make the bullets to fit it, rather than having the bullets and designing the gun barrel for them.

The two-part design section is an aid to people making hard and soft alloy bullets of two sections, a nose and a shank, which are swaged together to form one bullet. Given a desired bullet weight, it will calculate the volume and weight of each of two different alloys that will provide this, in a specified shape. The cost section asks you for the weight of your bullet, and the cost of the material in specified spool weights (for example, a 10-lb spool of .430 lead wire). The assumption is that you will want to know how many bullets you can make of a given kind from a certain supply of wire, and how much each bullet will cost you by the time you have paid both for the wire and shipping. You can also use this to calculate the cost of bulk lead such as ingots or wheelweights, in relation to cost per bullet, and to figure out how many inches to cut from a spool of a given diameter wire to produce a certain weight of bullet.

The cost section asks you for the weight of your bullet, and the cost of the material in specified spool weights (for example, a 10-lb spool of .430 lead wire). The assumption is that you will want to know how many bullets you can make of a given kind from a certain supply of wire, and how much each bullet will cost you by the time you have paid both for the wire and shipping. You can also use this to calculate the cost of bulk lead such as ingots or wheelweights, in relation to cost per bullet, and to figure out how many inches to cut from a spool of a given diameter wire to produce a certain weight of bullet.

Additional and more detailed information about lead wire extrusion and powder metal technology can be obtained with the Corbin DC-LEAD software, which helps you design extruders and compare lead production with different alloys, determine required cylinder and drive pump sizes, and required extrusion pressure to make your own lead wire in any size from any alloy.

Start writing here...

About Corbin DC-1003 Paper Patch Designer Software