The Corbin Bullet Knurling Tool (HCT-2) creates diamond-pattern knurling on lead bullets. The diamond knurls form tiny "waffle" patterns on the bullet surface, which hold lubricant like a waffle holds syrup: up to 200 percent more lubricant in contact with the bore than conventional grooves.

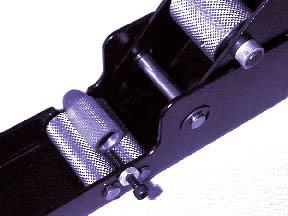

The lead bullet is placed on a knurled roller V-way, and a steel embossing wheel is brought into contact with the other side of the bullet by lowering a large, expanded-neoprene covered grip and pressing down upon the bullet while you turn a small crank one or two spins. The massive grip and long leverage makes the job easy even with the largest lead slugs.

The tool is designed for any caliber between .224 and .720 diameter and adjusts automatically for diameter of bullet in two ranges, from .224 to .458, and from .375 to .720. To select the range, remove one e-clip and put the pivot pin in the alternative set of holes linking the top and bottom of the device together. This means the same tool can be used to cover all calibers from 22 to 12 gauge shotgun!

The hard chromed precision ground steel roller V-way supports the bullet horizontally, so you can press straight down for maximum leverage and ease of use. Since both ends of the rollers are supported in the steel frame, there is no "creep" caused by spreading of one end of the supports, a common complaint with certain earlier brands of cannelure tools. Each bullet looks just like the last. |

Questions? |

Start writing here...

Can I use knurling on cast bullets?

Can I use knurling on cast bullets?

About Corbin Bullet Knurling Tool