Bullet Balls are precise diameter and weight polymer balls, available in five color-coded diameters, which can be used to make lighter-weight bullets by taking up some of the volume within a bullet jacket. By adjusting the position and ratio of core to ball, the balance of a bullet can also be adjusted, making it possible to use long or light bullets with standard twist rates of barrels.

For example, a bullet ball of proper diameter to drop into a .308 jacket (.25-inch diameter ball) will shift the weight forward if a short lead core is placed on top of it. Thus, a long jacket can be used to make light bullets, much lighter than would be possible without using a shorter jacket or having too much open tip area, without the ball.

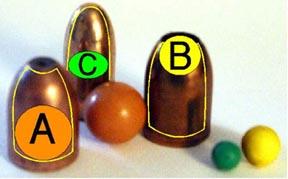

Corbin Bullet Balls are available in these sizes: | |||||

| Picture | Catalog No. | Color | Diameter (in.) | Lead Displacement (gr.) | Weight (gr.) |

| BB-1/8 | White | .125 | 2.9329 | 0.3 |

| BB-3/16 | Green | .1875 | 9.8984 | 1.0 |

| BB-1/4 | Yellow | .250 | 23.463 | 2.4 |

| BB-5/16 | Blue | .3125 | 45.8261 | 4.1 |

| BB-3/8 | Red | .375 | 79.1875 | 6.3 |

| Lead displacement is the weight reduction of a bullet for each ball used to replace an equal volume of pure lead core. |

The ball can be compressed in the jacket before the lead is inserted and seated, if you use a core seating punch that fits the jacket ID near the bottom. The standard punch usually fits near the mouth. The jacket usually becomes thicker walled near the base, and thus the ID becomes smaller. Sometimes, it is possible to use the core swage die's external punch to seat the ball. The ball should be as snug a fit as possible in order to fill the jacket and avoid shifting to one side, which would put the bullet core "off center". |

The bullet balls, available in packages of 1000, can also be used for bullet tips. By making the opening of a bullet just smaller than the ball diameter, any size of ball can be used that will fit within the jacket. This makes it possible to make "ball bearing" type tips, which roll the bullet up the feeding ramp, into the chamber, for more reliable feeding. |

Ultra-Light, high velocity bullets are fun to build using one or more bullet balls in the same jacket, topped with a small lead core to give the bullet some forward mass and restore accuracy. Most light weight bullets are short and tend to tumble, but the polymer filling topped by a bit of lead will help keep the nose pointed forward, and the shank can be just as long as any other weight of bullet. This allows the bullet to be loaded into a case neck properly, to fit the chamber or leade of the barrel, and to align correctly in the bore. The long, arrow-like bullet will tend to fly straighter than a stubby conventional light-weight bullet (although light weight means low BC, so the bullet will be affected more by cross winds and will drop more quickly than a heavy bullet). |

Start writing here...

The linear polyethylene polymer from which the bullet balls are made will elongate or flatten under pressure, but will tend to spring back to the original shape when pressure is released. The balls cannot be used to make a very sharp pointed tip, since they will go back to a somewhat oval shape after the pressure is removed. If they are pushed into too sharp a point, in fact, the material will tend to crack or deform rather than smoothly spring back. To make a small tip, use a ball that fits just below the jacket end and allow slightly less than half the diameter to protrude from the jacket. A .125-diameter ball (1/8) can be used for a small tip on a .224 or .243 bullet. A .1875-diameter ball (3/16) can be used as a small tip on a .284 or .308 bullet. There is no absolute rule as to what size you have to use...anything works if it pleases you. The closer the ball diameter becomes to the jacket ID, the more blunt the tip will be.

The linear polyethylene polymer from which the bullet balls are made will elongate or flatten under pressure, but will tend to spring back to the original shape when pressure is released. The balls cannot be used to make a very sharp pointed tip, since they will go back to a somewhat oval shape after the pressure is removed. If they are pushed into too sharp a point, in fact, the material will tend to crack or deform rather than smoothly spring back. To make a small tip, use a ball that fits just below the jacket end and allow slightly less than half the diameter to protrude from the jacket. A .125-diameter ball (1/8) can be used for a small tip on a .224 or .243 bullet. A .1875-diameter ball (3/16) can be used as a small tip on a .284 or .308 bullet. There is no absolute rule as to what size you have to use...anything works if it pleases you. The closer the ball diameter becomes to the jacket ID, the more blunt the tip will be.

About Corbin Bullet Balls